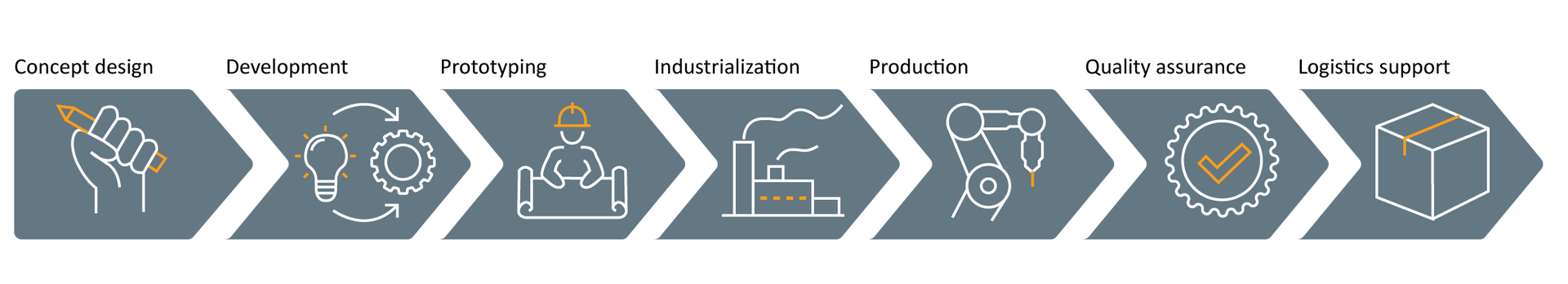

Product development

Creating a product that will set you apart from your competitors is challenging. Extensive expertise and many years of experience enable us to design, develop and manufacture products with high added value while guaranteeing consistent high quality and an excellent price-performance ratio.

CONCEPT DESIGN

Understanding the needs of a customer and reflect them in the final product is essential. During concept design we define product performance, while also tune and customise it across various customer needs. Next step that we take is to define the best product architecture, recognise and mitigate risks, control cost, features and time to market.

Benefits:

- Reliable & cost-effective product that fully meets customer’s requirements

DEVELOPMENT

During development we will work closely with you, guide you through the complete development process, and once your product is developed, we will produce it in our factory.

Product development consists of technical specification and requirements definition, architecture definition, BOM optimization, HW, SW and mechanical designs, electric and thermal simulations, optics simulation and design, functional tests, end of line test equipment design, highly accelerated lifetime tests and packaging design. Design processes follow known project management standards.

Benefits:

- Turning your idea into a product

- Cooperation in product design, project milestones and product documentation

- Full product service support

- Reduce product costs

- Serial production

- Enhance and optimize manufacturing processes

- Improve product quality and reliability

- Speed up time to market

- Enhance user experience and increase customer satisfaction

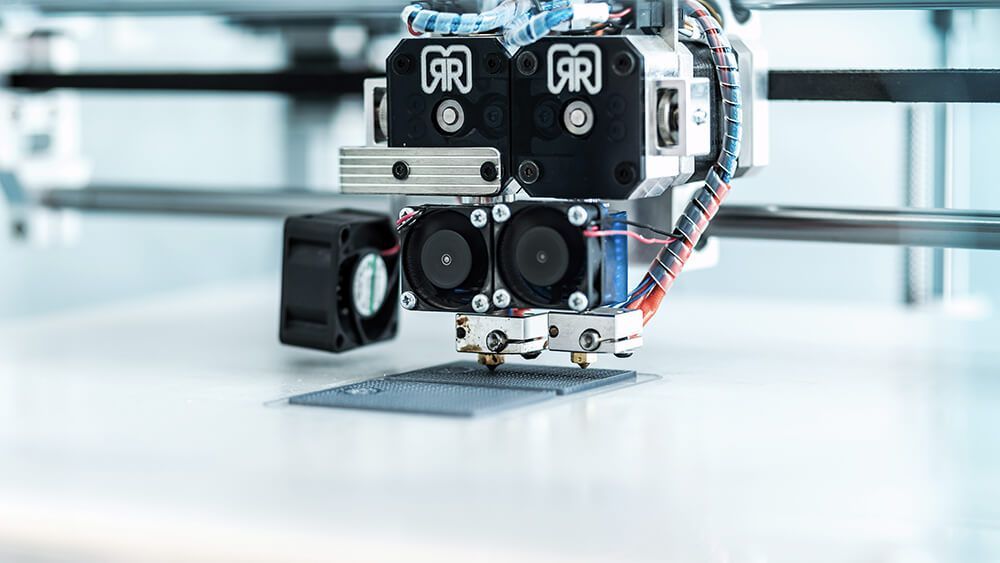

PROTOTYPING

With prototyping or low volume assembly we offer you full service of manual or automated PCBA assembly, including 3D prints and support assembly parts. Prototypes allow you to test a form and functions, present them to your customer or stakeholders, ensuring they have been designed appropriately for manufacturing.

Benefits:

- Test all properties, electrical, mechanical, functional and user experience before serial production

- Present product to customer

- Improve production processes

- Check market and get feedback before serial production

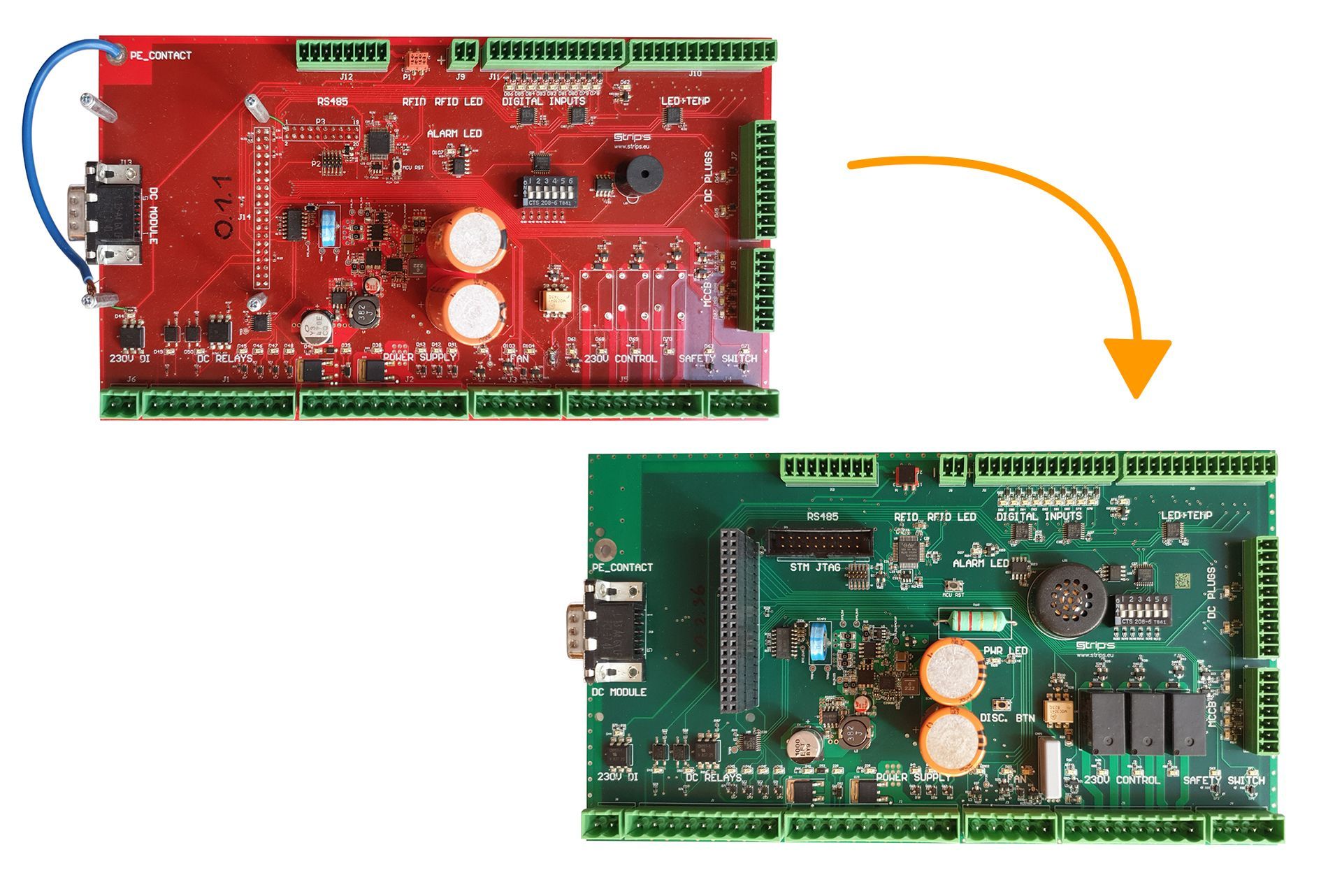

INDUSTRIALIZATION

Strip’s is design for manufacturing oriented. With the experience in APQP/PPAP all projects are coordinated with standardized reviews and the predictable project flow. Tools such as DFMEA enable us to analyse manufacturability in early stage of development and consequently reduce product costs.

If required, we will take full care of individual product certification. This is taken into consideration already during the development phase, which leads to quicker and easier product certification process.

As EMS provider Strip’s is using broad set of test methods and test equipment and we have knowledge and experience for consistently ensuring high quality levels.

Benefits:

- Reduced time to market

- Reduced costs

- Robust product

- Design for test

GET IN TOUCH

We will get back to you as soon as possible.

Please try again later.